Demystifying Pipe Identification Banding: A Comprehensive Guide

Complex piping systems are integral to various industries. Ensuring operational safety and efficiency is crucial. This blog post focuses on pipe banding, which is critical for differentiating between pipes and providing essential information about their contents and purpose. We will delve into its importance, guidelines, and best practices.

Why Pipe Identification Banding Matters:

Pipe identification banding is vital for several reasons:

- Safety: Proper pipe identification helps avert accidents and potential hazards. Particularly in environments with diverse and complex piping systems. It allows workers to immediately recognise pipe contents. Facilitating safer handling and appropriate precautions.

- Compliance: Industries must adhere to Health and Safety Executive (HSE) guidelines. which include specific requirements for pipe labelling and colour coding. Compliance ensures adherence to safety standards and eases inspection processes.

- Operational Efficiency: Accurate and clear pipe labelling helps in maintenance and troubleshooting. Enabling quick identification and understanding of pipe functions, thus minimising operational disruptions.

Pipe Identification Banding Guidelines:

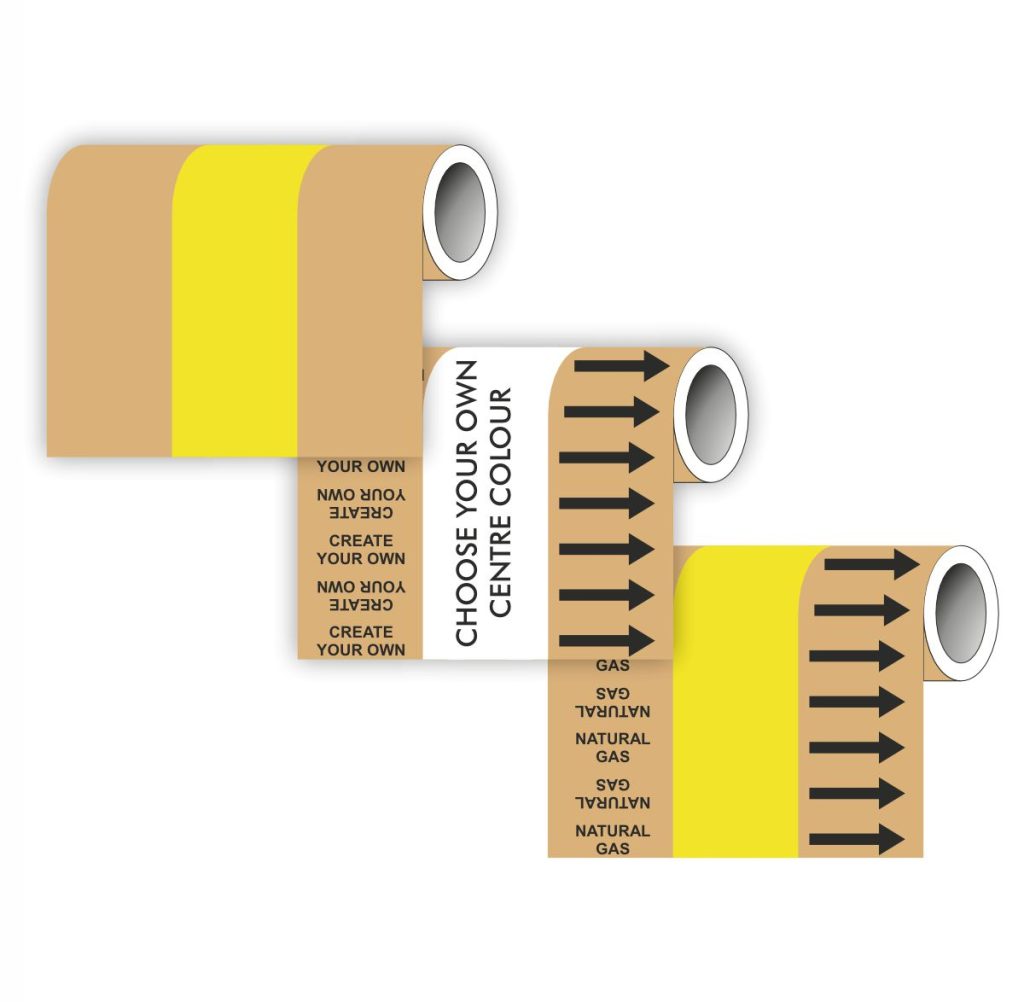

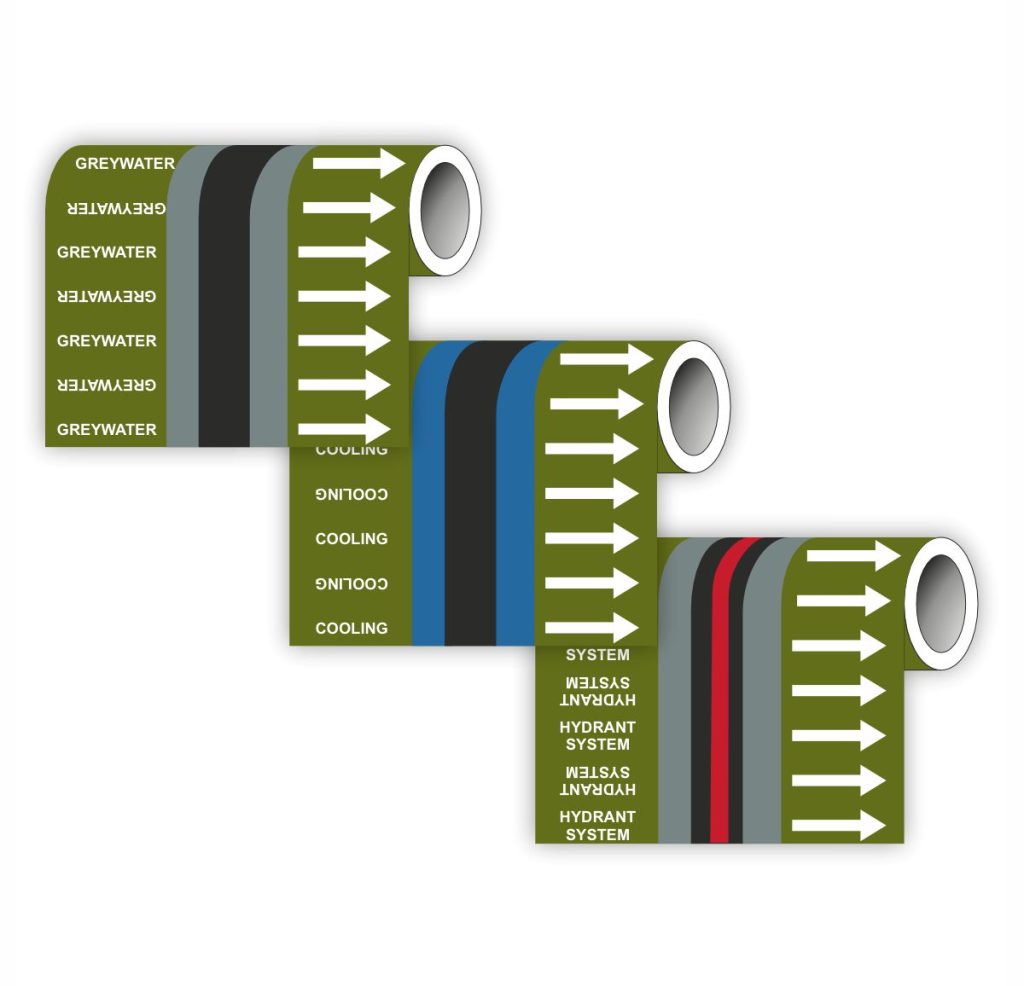

- Colour Coding: Standards for UK pipe colour coding. Standards may differ from those in other regions. Common colours include;

Common base colours include;

Yellow Ochre: Gases (flammable and non-flammable)

Light Blue: Air

Green: Water

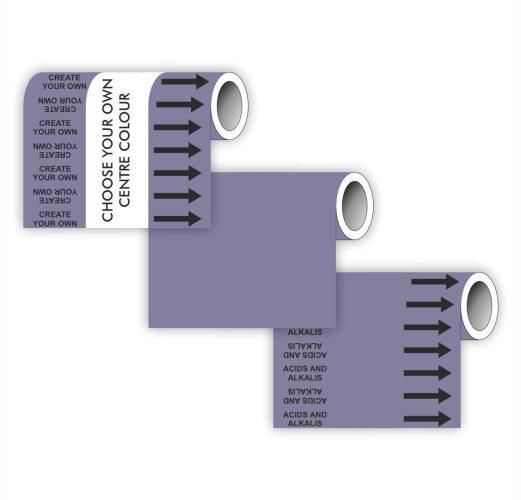

Violet: Acids and Alkalis

Grey: Steam

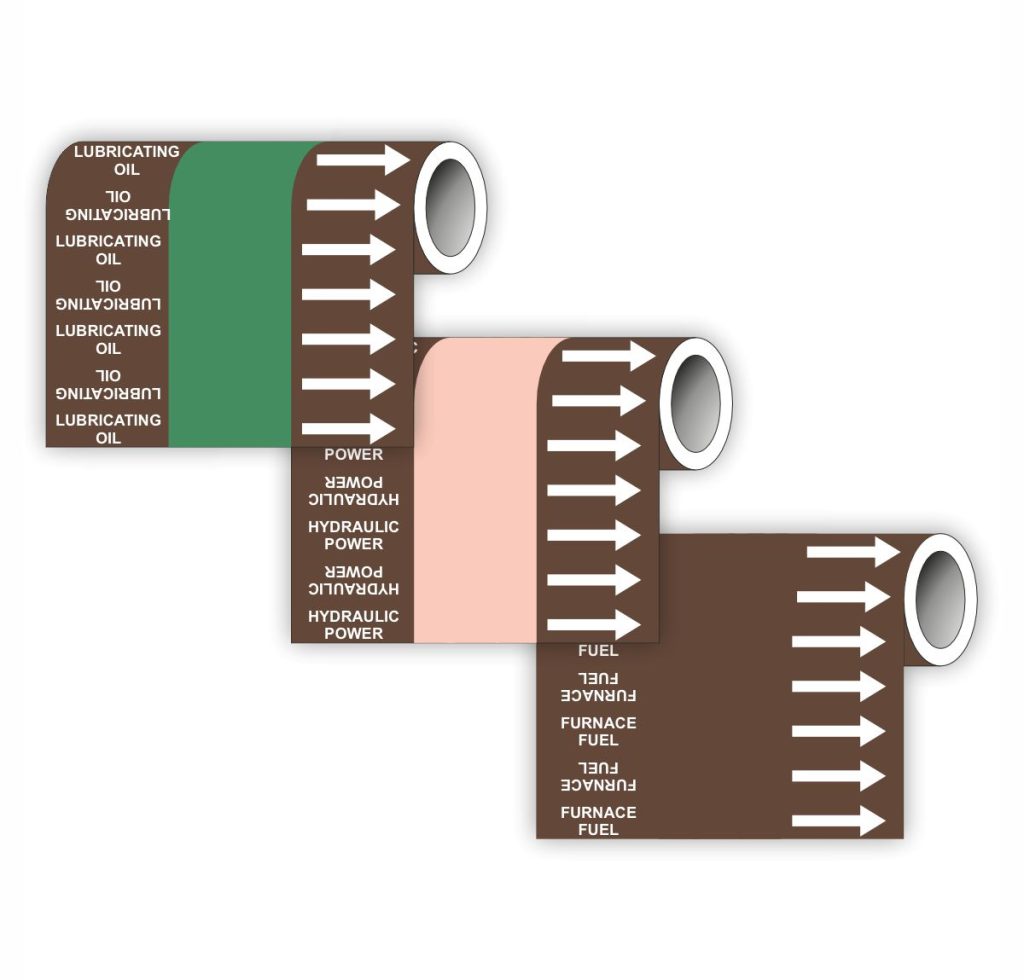

Brown: Oil

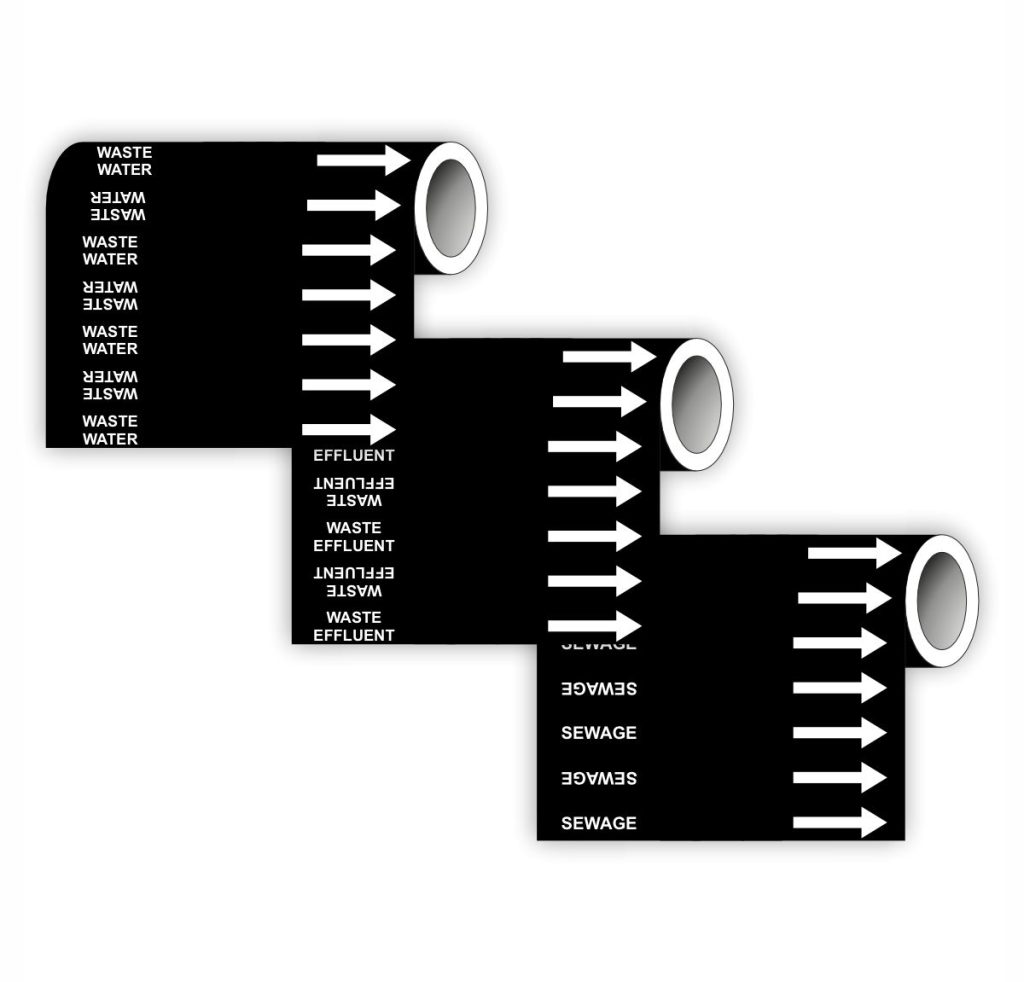

Black: Waste

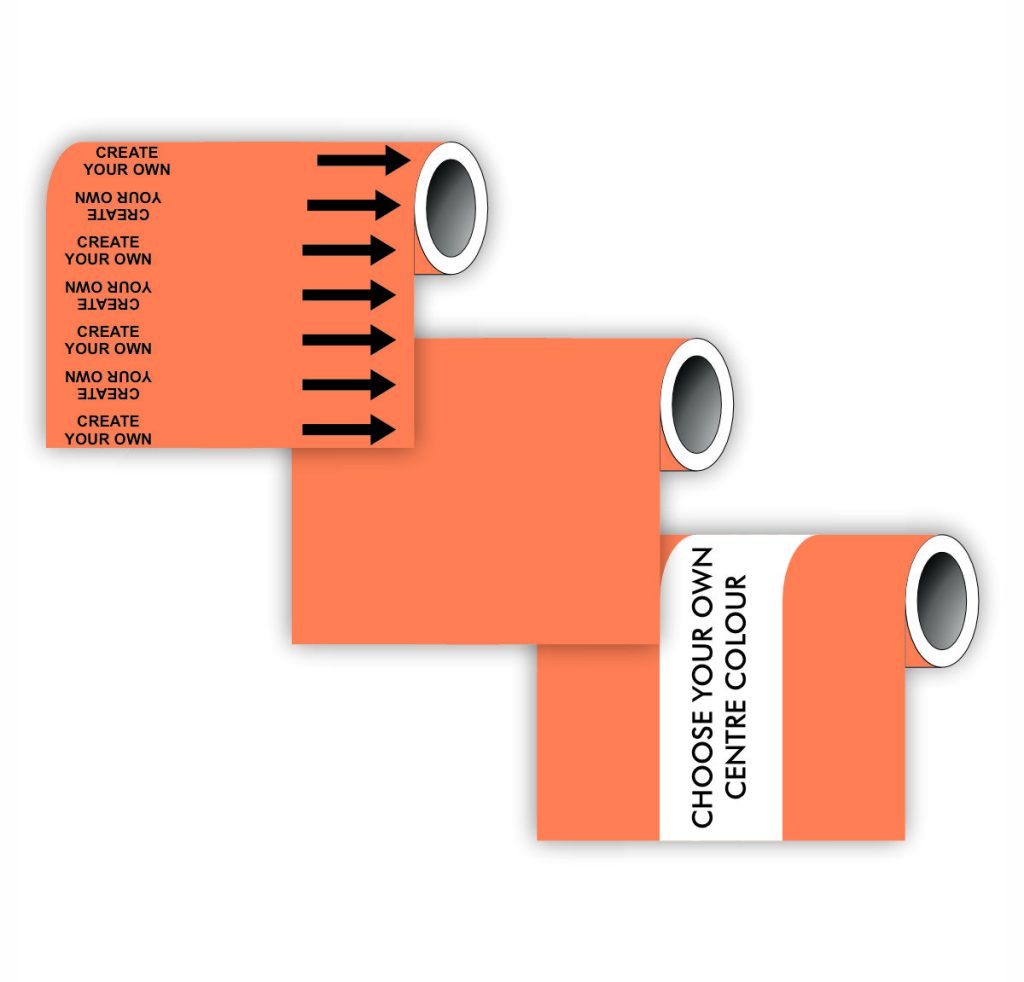

Orange: Electrical

Red: Fire

All of these colours can be combined with central bands to add an increased level of information. We will dig into the bands in a further blog.

Always refer to the latest HSE guidelines or British Standards for accuracy.

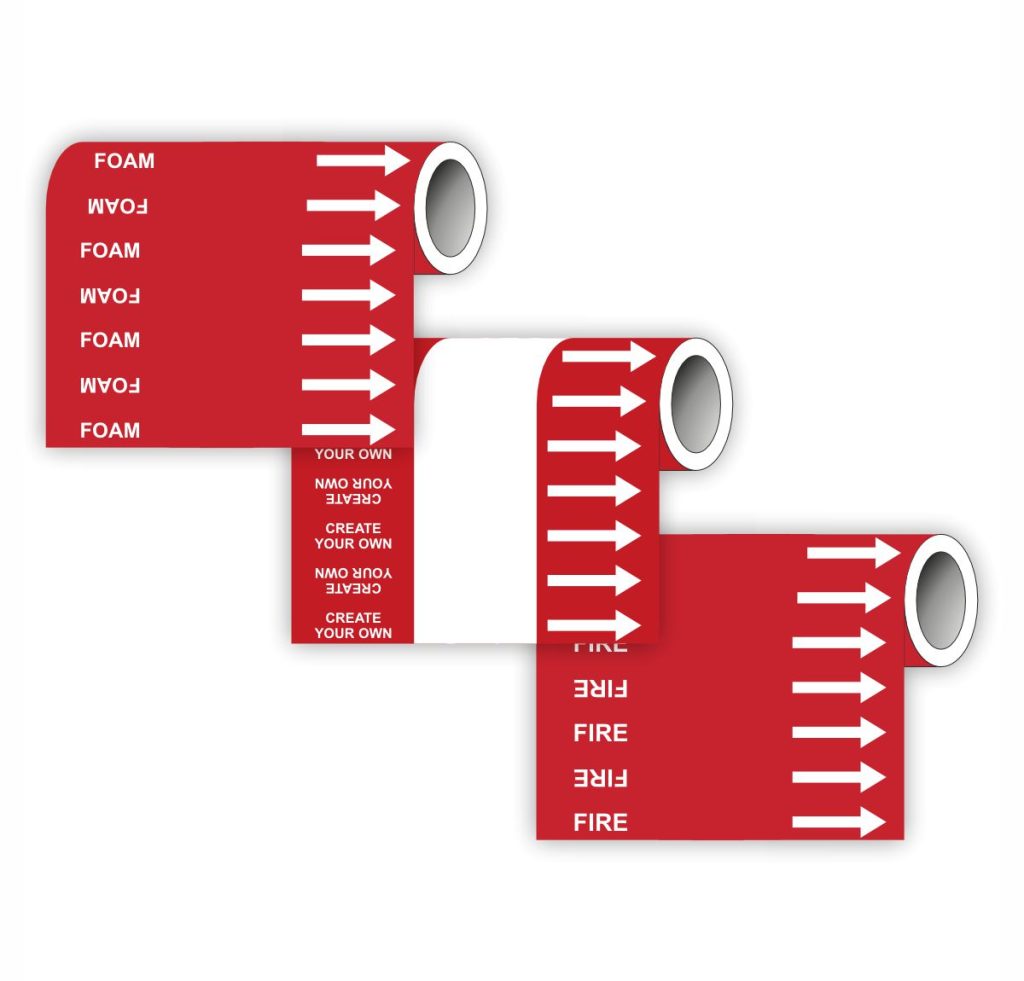

- Labelling: Alongside colour coding, it's vital to include clear text labels on pipes. Labels state the pipe's contents, direction of flow, and any hazards or warnings.

- Placement: Install identification bands at regular intervals, especially near valves, junctions, or changes in pipe direction. This ensures visibility from various perspectives.

Best Practices for Pipe Identification Banding:

- Consistency: Maintain standardisation across your facility. Install uniform colour codes and labelling, aligning with UK-specific regulations. This uniformity aids in easy recognition and interpretation of the pipe markings.

- Durability: Opt for high-quality, durable materials for your pipe marking tapes or bands. These should withstand environmental factors like humidity, chemical exposure, and UV light ensuring longevity and legibility.

- Training and Awareness: Train your staff about the pipe identification system. focusing on the specific colour codes and label meanings. Enhanced awareness contributes to improved safety and efficiency.

Pipe banding is fundamental in maintaining safety, regulatory compliance, and operational efficiency. Implementing a systematic approach to colour coding, labelling, and band placement. Is key to minimising risks and optimising maintenance and operational procedures. Pipe identification requires regular consultation with HSE regulations and British Standards.

For any more information on pipe banding or any other products please call us on 01348 840 675 or email info@rmlabels.com.

You can also view our full range here!

All the best,

R M Labels